GUANGZHOU B.D NEW BUILDING MATERIALS TECHNOLOGY CO.LTD

Website: www.ovsion.com

13302568785 (WeChat same number) Miss Li

Fixed call: 020-87391896

E-mail:2517172559@qq.com

Address: Room 1413, 14th floor, Dongjian building, 503 Dongfeng Middle Road, Yuexiu District, Guangzhou, Guangdong, China

Waterproofing is a very important part of home decoration, and choosing a waterproof coating plays a key role in waterproofing. In the proportion of investment in home renovations, waterproof materials account for only a small share, but it directly affects the safety and comfort of daily life. There is a wide variety of waterproof coatings on the market. Before purchasing, the necessary knowledge reserves will be available to help you choose the right waterproof material.

Waterproofing is the same as other concealed projects. If you do not do it well, the troubles that come later will be very great. In general, the basement of the house, the kitchen (kitchen decoration renderings), the bathroom (bathroom decoration renderings), the balcony (balcony renderings), and the roof garden (garden decoration renderings) are equal to the areas where the water is frequently exposed. Waterproof paint is used at this time, and the waterproof paint is a paint with special functions such as waterproof. Before you buy, you need to have a basic understanding of its basic knowledge and classification.

1, waterproof coating introduction

As the name suggests, waterproof coatings are coatings used to prevent water immersion and leakage. At room temperature, the waterproof coating is mostly in the form of a viscous liquid without a fixed shape. After coating, it forms a tough waterproof film on the base layer after curing by solvent evaporation or moisture evaporation or reaction.

2, waterproof coating classification

Waterproof coatings can be divided into organic waterproof coatings and inorganic waterproof coatings according to different film types. Organic waterproof coatings include reactive, water-emulsion, and solvent-based coatings; inorganic waterproof coatings include cement-based penetrating crystalline waterproof coatings and cement-based waterproof coatings that contain admixtures and admixtures.

The

Waterproof coating classification introduction

Organic waterproof coating

Water emulsion type waterproof coating

Water-emulsion asphalt-based waterproof coating, polymer cement waterproof coating, polymer emulsion waterproof coating (including acrylic acid, ethylene vinyl acetate, etc.), water emulsion silicone rubber waterproof coating

Reactive waterproof coating

Polyurethane waterproof coating (including single-component, water-curing, two-component, etc.), polyurea waterproof coating, epoxy resin modified waterproof coating, reactive polymer cement waterproof coating, etc.

Solvent type waterproof coating

Solvent-based asphalt-based waterproof coating

Inorganic waterproof coating

Including cement-based penetrating crystalline waterproof coating, cement-based waterproofing coating containing admixture and admixture

Most of the waterproof coatings on the market are organic waterproof coatings. The organic waterproof coating can be divided into three types of water-emulsion-type waterproof coating, reactive-type waterproof coating, and solvent-based waterproof coating, depending on the form of the film-forming substance.

Aqueous emulsion-type waterproof coating: This type of waterproof coating is a polymer material that is the main film-forming substance. It is suspended in suspension (not dissolved) in tiny particles (rather than in a molecular state) in water and becomes a latex-like coating.

Features: Through the evaporation of water, after the solid particles approach, contact, deformation and other processes and conjunctiva; coating drying is slow, the density of a film formation is lower than that of solvent-based coatings, generally not under 5 °C; storage period is generally not more than six months Can be applied on a slightly damp grass-roots base; non-toxic, non-flammable, safer in production, storage, transportation, and use; easy to operate, without polluting the environment; lower production costs.

Reactive water-repellent coating: This type of waterproof coating is used as the main film-forming material of the polymer material in the liquid state of the prepolymer. Mostly composed of two-component or single-component coatings, almost free of solvents.

Features: The liquid polymer prepolymer reacts with the corresponding substances to form a conjunctiva; a thick coating film can be formed at once, without shrinkage, and the coating film is dense; the two-component coating needs to be accurate on the spot of 1:2. Stir well to ensure quality; more expensive.

Solvent-based waterproof coating: In this type of coating, a polymer material that is the main film-forming substance is dissolved in an organic solvent and becomes a solution. Polymer materials are stored in solution (paint) in a molecular state.

Features: Through the solvent volatilization, after the polymer molecular chain contact, overlap and other processes and conjunctiva; coating drying fast, thin and dense conjunctiva; production process is relatively simple, the coating storage stability is good; flammable, explosive, toxic The safety of production, storage and use should be paid attention to; due to the rapid volatilization of solvents, there is pollution to the environment during construction.

Part2: Avoid entering the wrong area Choose the waterproof coating

Due to the limited understanding of waterproof coatings, consumers can easily enter into several purchase errors when choosing waterproof coatings. Understand these misunderstandings, although it can not guarantee that consumers can solve the purchase problem by themselves, but can prevent consumers from repeating these more prone mistakes.

Myth 1, think that waterproof coating has nothing to do with environmental protection

Home improvement decoration waterproofing project is a relatively concealed project, some families often mistakenly believe that the bathroom, kitchen (kitchen decoration renderings) and other interior decoration waterproof engineering area is not very large, after the use of waterproof coating on the cement and tiles It will not cause pollution. In actual fact, because of the concealed nature of the waterproof layer, the use of inferior waterproof paint will pollute the indoor environment for a long time. Therefore, the selection of waterproof paint must not be taken lightly.

Myth 2, think that the softer the waterproof coating, the better

When people talk about waterproofing, the subconscious and intuitive perceptions are mostly limited to the application of flexible materials. It is considered that the flexible material is left, and waterproofing is not completed or the more flexible the waterproof effect is, the better. However, flexible materials focus on the formation of a waterproof coating layer. Rigid waterproofing solves the problem internally and has its own advantages and characteristics. It is best to be gentle and soft.

Myth #3: Think of waterproof paints as bright as possible

At present, some companies in the market have introduced waterproof materials that are colored after construction and are widely publicized. However, it should be noted that the quality of products should be judged mainly by their technical indicators rather than color. Therefore, the waterproof paint does not look as bright as possible.

Misunderstanding four, different parts are selected the same waterproof coating

There are differences in performance requirements for waterproof coatings in different spaces. Therefore, when choosing a waterproof coating, waterproof materials should be used according to different parts. Only by using local materials to “do their best and use the best materials” can the best be achieved. Good waterproof effect. On the contrary, improper use of waterproof material is also very harmful.

Part3: smart consumption method waterproof paint purchase tips

Waterproof coating is the basic material for the most advanced field in home decoration and has a great impact on the quality of future decoration. However, these relatively "raw" forms of materials for the first time the decoration of the consumer, you know, you may not see even the most. As everyone knows, many of them have a lot of doors and they really have to work hard when they buy.

1, determine the amount of waterproof coating

Before you buy waterproof paint, you must first measure the waterproof construction area. Then calculate the total amount of waterproof coating needed for each square meter of waterproof coating product. That is the amount of waterproof coating = waterproof construction area * per square meter of coating amount. In this way, it is possible to avoid the shortage or waste of the waterproof coating that caused the purchase.

2. Select different waterproof coatings according to different construction locations

To purchase waterproof coatings, you need to select the different functions of the room and the construction site. Because different parts have different requirements for waterproofing, so this is the key to making waterproof and impervious, otherwise it will seriously affect the waterproof quality and durability.

Roofing waterproofing layer: The waterproof layer is exposed to nature, exposed to hot sunlight, wind blows, erosion of rain and snow, extreme temperature and heat, no good performance and good protection measures, it is difficult to reach the required endurance period . Therefore, a waterproof material with high tensile strength, high elongation, and good aging resistance should be selected.

Basement waterproof layer: The basement is soaked in water or very moist soil for a long time, and the ventilation condition is not good. The waterproof material must have good water resistance and moisture resistance, strong resistance to water pressure, and no environmental odor.

Kitchen, bathroom between the waterproof layer: kitchen and toilet room is not affected by the external climate, temperature changes little, the material's elongation rate requirements are not high; the second is a small area, yin and yang angle, more floor pipe; three is the wall Paste tiles on the surface of the waterproof layer must have good affinity with the adhesive. According to the above three characteristics, select better waterproof products such as water resistance and adhesion.

3, waterproof coating purchase considerations

Pay attention to the waterproof property of the product: The most basic function of the waterproof coating is waterproof, so whether the waterproofness is good or not is a decisive factor in determining the quality of the product. When purchasing, it is important to pay attention to the waterproofness of the product.

Pay attention to the environmental protection of the product: Waterproof is a hidden project. After waterproofing, it is tiling. If toxic materials are selected, it is like a "poison gas bomb" buried at home. It releases poison gas for a long period of time and it is difficult to replace it. Therefore, it is difficult to replace it. The environmental protection of materials is also a very important aspect of purchasing materials.

Identify the authenticity of waterproof coating: look at the packaging, whether it meets the requirements of branded product packaging, bright colors, clear writing, according to the standard product name, net weight, explain the place of origin, certification and other requirements. Most well-known brands have their own security signs. Be careful when buying.

Part4: construction is not lost construction points of waterproof coating

Choosing a waterproof coating doesn't mean that waterproofing is completely foolproof. If something goes wrong during construction, it will bring unnecessary trouble to the future, especially for self-installed friends. Therefore, it is necessary for us to understand the construction points of the waterproof coating.

1, do a good job at the basic level

Before the waterproof construction, it is necessary to do a good job in the primary treatment of the wall, and it is necessary to ensure that the surface of the primary layer is solid, non-powdering, peeling, and drumming. At the same time, the surface of the base must be clean, free of dust, mold release agents, etc., which will affect the adhesion of the paint. And the base surface should be flat, no major defects, no obvious traces.

The treatment method is to first carefully remove the dust on the base surface and remove the cement agglomeration and loosening of the base layer; special treatment shall be performed on the roots, drain holes, yin and yang angles, and voids left on the wall after the hydropower reform, and the yin and yang corners should be wiped. Rounded (or V-shaped). After processing, use a brush to sweep the dust on the base surface, dilute the appropriate amount of waterproof paint to milk, and dip the diluted material to the bottom with a roller. Brush the water-repellent surface on the front wall and back wall to completely remove dust.

2, brushing waterproof coating

General brush waterproof height can be determined according to need, in general, bathroom waterproof 180 cm high, non-shower wall in principle, waterproof paint can not be less than 35 cm. However, in order to enhance the waterproof effect, it is recommended to achieve a uniform height of 180 cm. In addition, it is recommended that the waterproof height be the top for light walls and self-built light walls that have been remodeled in toilets. Waterproof coatings must be brushed to the 1.5mm thickness of the National Acceptance Specification.

Different waterproof coating construction methods are not the same. However, when brushing, it is similar to general liquid paint. It is brushed from the bottom to the top and back to the front wall. When using, if there is a bubble in the slurry, it is necessary to brush the bubble and there must be no bubbles. The first pass only needs to be painted in one direction, and the second pass is painted in the opposite direction. The first and second brushing intervals are preferably around 4-8 hours.

3, do a good job of closing the water test

Closed water test is an important test method for checking the waterproof quality of the interior. After the waterproof project is completed, seal the door and the water outlet and fill the room with water to a certain liquid level. If there is no significant drop in the liquid level within 24 hours, it is qualified. After the water-retaining test is completed, a layer of cement mortar protective layer is applied on the waterproof coating layer, taking care not to damage the already prepared waterproof coating layer. After the protective layer of cement mortar dries out, it can be plastered with a wall tile or a spray paint for normal decoration.

Recommended News

- 18-03-21 Ground hardener (carborundum) standard implementation process

- 18-02-28 What is the difference between the metal and nonmetal in the diamond wear-resistant floor?

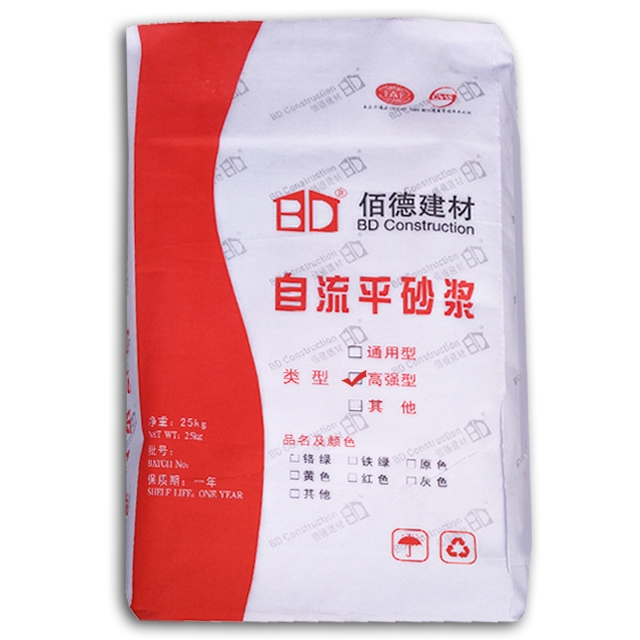

- 17-12-08 How much is a square of self-leveling? Self-leveling price?

- 18-03-30 The first choice of concrete sealing and curing agent for dustless ground

- 17-12-08 Emery primary color workshop floor case

- 17-11-30 How to choose a waterproof coating product?

- 17-11-30 The key to difficult construction of wear-resistant floor is process and technology

- 17-11-27 Seven errors in the use of tile adhesives