GUANGZHOU B.D NEW BUILDING MATERIALS TECHNOLOGY CO.LTD

Website: www.ovsion.com

13302568785 (WeChat same number) Miss Li

Fixed call: 020-87391896

E-mail:2517172559@qq.com

Address: Room 1413, 14th floor, Dongjian building, 503 Dongfeng Middle Road, Yuexiu District, Guangzhou, Guangdong, China

Polymer cement mortar waterproof latex

Polymer cement mortar waterproof latex is made of imported polymer architectural emulsion, supplemented by a variety of composite additives. Incorporation into the cement mortar can form a unique composite network structure with certain toughness, greatly improving the crack resistance and impermeability of the cement mortar. Due to the different types of polymer emulsion, this product is divided into three types: A, B, and C.

product advantages

1. Double the bond strength of cement mortar;

2, with excellent impermeability, crack resistance, impact resistance;

3, high temperature resistance, good alkali resistance;

4, the product is non-toxic, harmless, non-polluting, is an environmentally friendly product.

Scope of application

1. Waterproof and anti-leakage works on various parts of the external walls, roofs, toilets, baths, and pools;

2. Waterproof and anti-leakage works for underground works such as basements, tunnels, embankments, and subways;

3, especially suitable for aerated concrete, hollow bricks and other porous materials wall anti-seepage wipe or brushing.

user's guidance

1, the main materials and requirements:

1Cement: General use Portland cement with strength class not less than C32.5;

2 Sand: According to different construction objects, medium sand or fine sand;

2, preparation:

1 cement paste preparation, it only needs to formulate the ratio of cement and latex can be mixed with the right amount of water, the amount of latex is about 0.1kg / m;

2 When the waterproof mortar is prepared, dry the cement and sand according to the formula proportion, then add the specified latex and water, and mix it evenly with a mechanical or manual method. Prepared waterproof mortar at room temperature (20 ± 2 °C), preferably within 1 hour.

3, construction:

1 Basis treatment: The mortar (or concrete) should be smooth and solid. The surface dust, dust, oil, etc. should be removed. The leaked water should be treated with plugging material first. For parts with different material contact between metal and plastic pipes. The surroundings should be polished.

2 waterproof mortar construction:

A. Brush the cement paste on the treated base surface to increase the adhesion to the base surface;

B. After the cement paste is not sticky, the mixed polymer cement mortar can be evenly scraped and wiped on the surface of the base layer and flattened and wiped with a trowel. The thickness is generally an outer wall of 3-5 mm; the basement, Pool: 5-8mm;

C. The polymer cement mortar shall be layered: After the first layer of polymer cement mortar is initially set, the second layer of polymer cement mortar shall be wiped until the required thickness (4 hours initial setting, 8 hours final setting);

D. After 24 hours of construction, wet maintenance is required. The curing time varies depending on the temperature conditions. It is appropriate to use 3-5 days at room temperature.

E. When pasting decorative materials, apply “cement, paste” or “waterproof mortar” on the surface of the base layer and the adhesive surface of the decorative material, and then apply them on the base surface and correct it.

Storage, Transportation and Packaging

1, should be sealed in a cool place, storage period of 12 months.

2. The three types of product packaging are: 4kg/barrel, 20kg/barrel, 50kg/barrel (can be used with 50kg/bag of cement)

Recommended News

- 18-03-21 Ground hardener (carborundum) standard implementation process

- 18-02-28 What is the difference between the metal and nonmetal in the diamond wear-resistant floor?

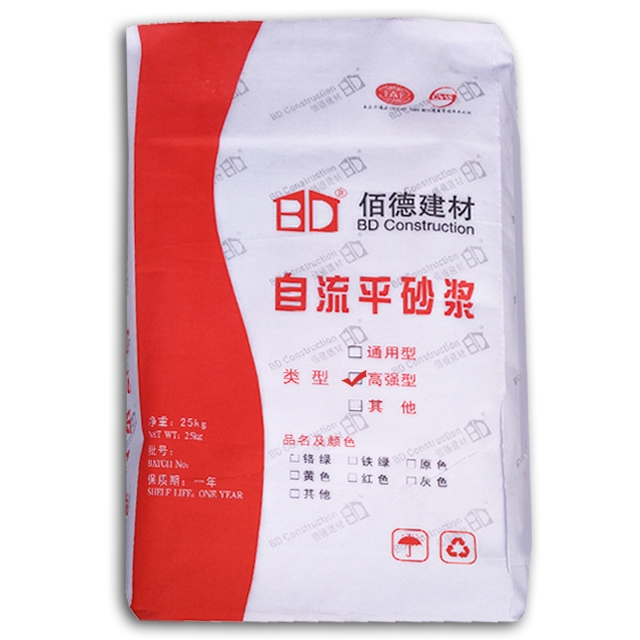

- 17-12-08 How much is a square of self-leveling? Self-leveling price?

- 18-03-30 The first choice of concrete sealing and curing agent for dustless ground

- 17-12-08 Emery primary color workshop floor case

- 17-11-30 How to choose a waterproof coating product?

- 17-11-30 The key to difficult construction of wear-resistant floor is process and technology

- 17-11-27 Seven errors in the use of tile adhesives