GUANGZHOU B.D NEW BUILDING MATERIALS TECHNOLOGY CO.LTD

Website: www.ovsion.com

13302568785 (WeChat same number) Miss Li

Fixed call: 020-87391896

E-mail:2517172559@qq.com

Address: Room 1413, 14th floor, Dongjian building, 503 Dongfeng Middle Road, Yuexiu District, Guangzhou, Guangdong, China

product manual

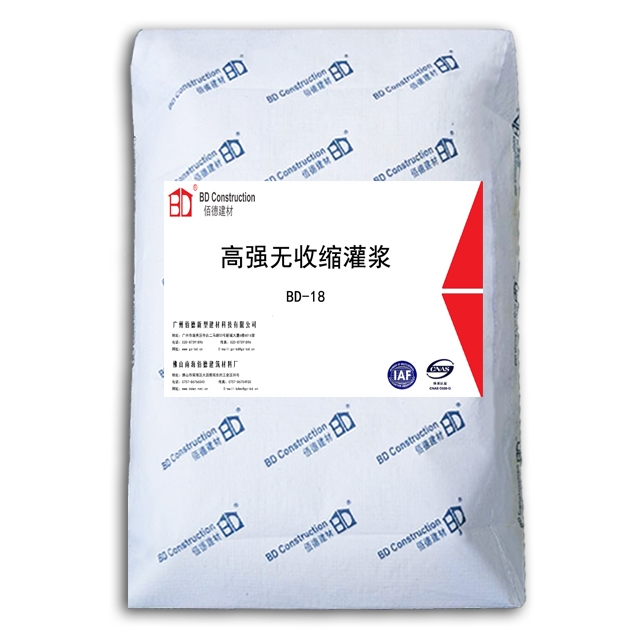

With the rapid development of economy, construction projects are increasingly developing in the direction of diversified functions, large-scale, high-rise super high-rise buildings, such as subways, tunnels, highways, dams, stadiums, convention centers, a-type factory equipment, high-rise office buildings... The number of various types of projects is increasing, and the corresponding supporting projects such as ground reinforcement, structural reinforcement, and equipment foundation reinforcement are also increasing, and the use of bureaucratic materials is becoming more and more widespread. At the same time as the economic and architectural development, the requirements for environmental protection are also increasing. Most of the grouting materials currently used are organic materials, have certain pollution, have higher prices, and have poor durability. Therefore, the development of environmentally friendly, economical, and highly durable grouting materials has significant economic significance.

BD-18 has good permeability and fillability similar to organic chemical grout, and it has higher strength, durability and environmental protection.

BD-18 can be used for building foundation reinforcement in complex soil geologic environments, reinforcing building structures, waterproof plugging grouting for buildings, and basic reinforcement of large-scale equipment, and can exhibit excellent performance.

Product features

1, early strength, high strength, 1-3 days compressive strength up to 30-50MPa or more.

2, high free flow: You can fill all the gaps to meet the requirements of secondary grouting equipment.

3, micro expansion agent: ensure close contact between the equipment and the foundation, no shrinkage after the second grouting. High bond strength, bond strength with steel not less than 6MPa.

4. Winter construction: It is allowed to carry out outdoor construction under the temperature of -10°C.

5, strong durability: This product is inorganic cement material, the service life is greater than the service life of the base concrete, after hundreds of fatigue tests, 50 times the freeze-thaw cycle test intensity did not change significantly, soaked in the oil 30 days after the strength increased significantly.

Scope of application

1. Deep foundation engineering blocks the flow of groundwater.

2. Reinforcement of dam foundations and filling of cracks in dam dams

3. Grouting reinforcement and repair of subway or tunnel walls.

4. Foundation reinforcement and repair of large or high-rise buildings.

5, road foundation grouting reinforcement and concrete prefabricated parts, beam box of horse, honeycomb defect repair.

6. Waterproof plugging grouting for pools, reservoirs and basements

7. Curtain grouting when excavating underground works such as subways, tunnels and mines

8. Solidified and reinforced treatment of sand layer foundation

9. Secondary grouting for anchor bolts and bases of large equipment.

10, planting anchorage.

Construction steps

1. Prepare mixing equipment, grouting equipment, formwork and maintenance articles, clean up the grouting space and water the concrete surface in advance to moisten it.

2. Set the template and use cement (sand) slurry, plastic tape sealing template joints to ensure no leakage, no leakage of pulp.

3, according to the grouting material weight of 12 ~ 15% of the amount of water plus water stirring (mechanical stirring 2min, manual stirring 5min)

4. Inject grouting into the grouting area in one direction. If necessary, use one-by-one or steel rods to divert the flow. Also, moderately or gently tap the template.

5. After the completion of construction, the curing agent should be sprayed or covered with plastic film or covered with mats. The geotextiles should be kept in the shade for 3-7 days.

6, the construction temperature is -15 °C ~ 40 °C, is strictly prohibited in the grouting material secondary incorporation of any admixture.

Technical Parameters

Item model | Compression strength (MPa) | Vertical expansion rate% | Fluidity mm | Slump mm | Rebar bond strength MPa | The largest aggregate particle size | |||

1d | 3d | 28d | Round steel | 28d | |||||

BD-18 | 25~40 | 40~55 | 60~75 | ≥0.02 | 270 | — | ≥6 | ≥13 | 6-8Head |

Relationship between film removal and curing time and ambient temperature

Daily minimum temperature(℃) | Demoulding time(h) | Conservation time(d) |

-10~0 | 96 | 14 |

0~5 | 72 | 10 |

5~15 | 48 | 7 |

≥15 | 24 | 7 |

Packing and storage

1. Packing: 25kg/bag

2. Shelf life is 6 months, beyond the shelf life should be re-examination qualified before use

Recommended News

- 18-03-21 Ground hardener (carborundum) standard implementation process

- 18-02-28 What is the difference between the metal and nonmetal in the diamond wear-resistant floor?

- 17-12-08 How much is a square of self-leveling? Self-leveling price?

- 18-03-30 The first choice of concrete sealing and curing agent for dustless ground

- 17-12-08 Emery primary color workshop floor case

- 17-11-30 How to choose a waterproof coating product?

- 17-11-30 The key to difficult construction of wear-resistant floor is process and technology

- 17-11-27 Seven errors in the use of tile adhesives