GUANGZHOU B.D NEW BUILDING MATERIALS TECHNOLOGY CO.LTD

Website: www.ovsion.com

13302568785 (WeChat same number) Miss Li

Fixed call: 020-87391896

E-mail:2517172559@qq.com

Address: Room 1413, 14th floor, Dongjian building, 503 Dongfeng Middle Road, Yuexiu District, Guangzhou, Guangdong, China

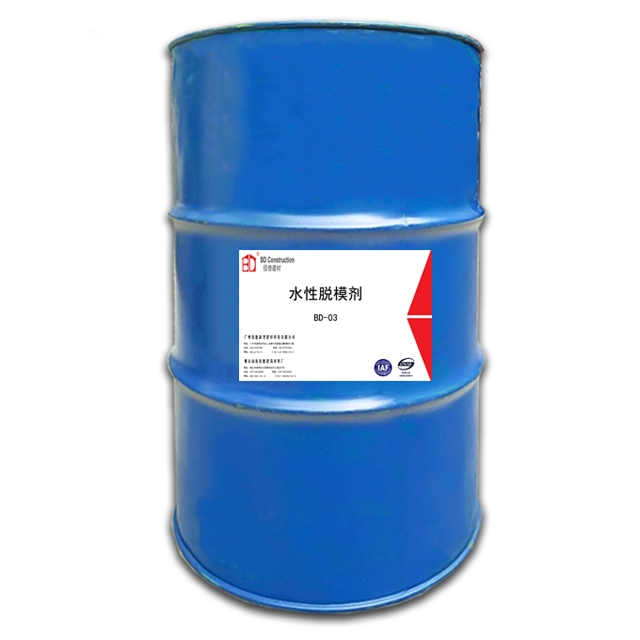

BD-03 water release agent

product manual

BD-03 is the crystallization of a variety of imported environmentally friendly pollution-free chemical raw materials and high-tech. This product has the advantages of strong hydrophobicity, good lubricating performance, easy mold release, wide applicability, etc. It has non-corrosive steel bars, machinery, and molds, and it plays a protective role for various types of templates. The surface layer of concrete is free from any pollution, and it has a lot of pollution. Fan ash has no side effects, and it has no pollution to humans, animals, water, plants, air, and soil. Suitable for wood molds, floor molds, steel molds, bamboo glue boards, etc.; especially suitable for demoulding of large steel mold beam boxes and preforms. It is an essential material for large-scale building construction units and concrete prefabrication plants and component plants. It is an ideal demoulding product on the market.

Executive standard

This product complies with the "JC/T949-2005 (2012)" standard

Scope of application

Wood molds, steel molds, floor molds, bamboo glue boards, etc. can be used, especially for large steel molds.

product advantages

Mouth water strong

Good lubrication performance

No corrosion

Mouth release and easy application, wide applicability

Instructions

1) Concentrated (1:2 or 1:3) proportioned water (that is, the agent: water = 1:2 or 1:3) can be used evenly after mixing.

2) Stir before use Mix the water in proportion and stir it evenly. Brush it directly on the template and pay attention to even brushing.

3) After the mold release agent is applied on the template for 30 minutes, the concrete can be poured. After demoulding, the surface of the concrete should be smooth without re-powdering.

4) After the mold release agent is applied on the template for 30 minutes, it has strong heat resistance and water resistance, and is not afraid of sunlight and rain. Demoulding does not affect the mold release effect after the test piece is soaked in water for two days.

5) The release agent is painted on the steel plate with good rust protection performance.

Product operation principle

1, emulsification and dispersion

BD-03 mold release agent is mainly composed of fatty acid, mineral oil, polymer surfactant and weak alkaline lubrication, mold release material compounded emulsion. In the emulsion, the secondary emulsifier molecules surround the microparticles of the film former, with the hydrophobic gene facing inward and the hydrophilic gene facing outward. The formation of dotted micelles, due to the repulsion of the same-sex charge, the uniform dispersion of the colloidal particles keeps the solution homogeneous, the viscosity is small, and it is not easy to coagulate and freeze.

2, lubrication and isolation

Due to the uniform emulsion stability, some of the oily substances can fully dilute good lubricity and film formation, protect the steel mold from corrosion, and form a film together with the saponified release material, and have good water resistance after film formation.

3, the role of reactivity

After the mold release agent is applied to the stencil, the surface of the stencil is first rendered hydrophobic, and the free hydroxide of the chemically active material in the in-mold fresh concrete acts as a saponification reaction to form a water-insoluble soap agent with physical separation effect, ie, to act as a lubricating agent. , again hindered or delayed the interface

The solidification effect of the concrete in the layer, the cohesive force of the surface concrete is destroyed when the mold is removed, and the effect of easy demoulding is achieved, and the surface of the concrete is smooth without re-powdering.

4, the dual role of mold release and maintenance

The water-insoluble film produced by the reaction of the release agent with the concrete not only plays a role in demoulding but also plays a role in curing the concrete.

Packing specification: 200kg/drum, 25kg/drum

Precautions

Keep sealed, pay attention to waterproof, shelf life of three years

Recommended News

- 18-03-21 Ground hardener (carborundum) standard implementation process

- 18-02-28 What is the difference between the metal and nonmetal in the diamond wear-resistant floor?

- 17-12-08 How much is a square of self-leveling? Self-leveling price?

- 18-03-30 The first choice of concrete sealing and curing agent for dustless ground

- 17-12-08 Emery primary color workshop floor case

- 17-11-30 How to choose a waterproof coating product?

- 17-11-30 The key to difficult construction of wear-resistant floor is process and technology

- 17-11-27 Seven errors in the use of tile adhesives